Deep Well Submersible Pump

Deep well submersible pumps are high-efficiency systems used to draw water from underground sources. They are widely preferred in agricultural irrigation, drinking water supply, as well as industrial and construction projects. With water-resistant bodies, high pressure capacity, and low energy consumption, deep well submersible pump solutions play a key role in modern water management.

In Turkey, the advanced technologies offered by Grundfos stand out with long-life motor design, quiet operation, and high efficiency. Thanks to features such as durability, energy efficiency, and easy maintenance, these pumps are trusted in both residential and industrial applications.

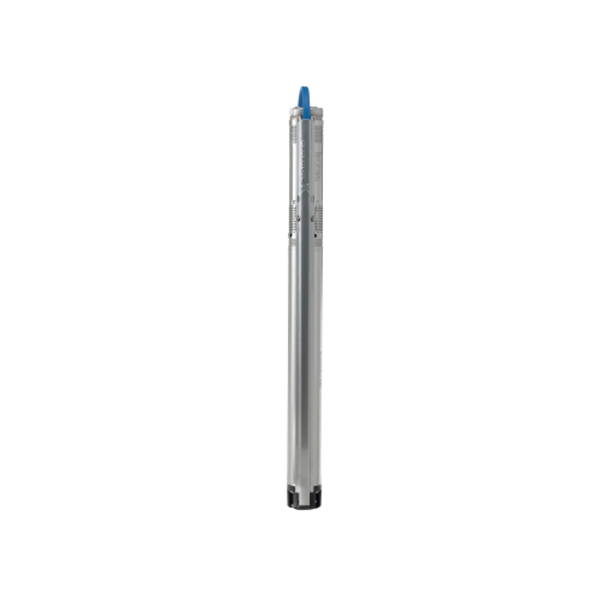

Grundfos Deep Well Pump

Grundfos deep well pumps are among the leading solutions for water supply, offering high efficiency and durability. They ensure safe and uninterrupted water delivery in agricultural irrigation, potable water systems, and industrial applications. Developed by Grundfos, these pumps feature long-lasting stainless-steel bodies, high-performance motors, and hydraulic designs that promote energy savings.

Grundfos deep well pumps are produced in various models to match different well depths and flow requirements. The QSP, SP, SQ, and SQE series are particularly notable. Equipped with modern technologies such as variable frequency control (VFD), these pumps can automatically regulate water pressure—reducing energy consumption and extending pump life.

Within the authorized network in Turkey, Poyan Engineering provides professional sales, installation, and technical service for these pumps. For project-specific pump selection and system configuration, you can consult their expert team.

Grundfos deep well pump solutions deliver quiet operation, low maintenance needs, and high hydraulic efficiency—ensuring both energy savings and long-term reliable performance.

Selecting a Deep Well Submersible Pump

Proper deep well submersible pump selection is critical for overall system performance. When choosing a pump, consider well depth, required flow rate, total dynamic head, and available power supply.

The answer to how to select a deep well submersible pump begins with accurately calculating the needed flow (m³/h) and head. An undersized pump leads to inadequate pressure, while an oversized pump wastes energy. For project-based analysis and brand–model matching, seek guidance from authorized partners such as Poyan Engineering.

Types of Deep Well Submersible Pumps

There are many types of deep well submersible pumps suited to different needs:

- Stainless-steel submersible pumps: Corrosion-resistant models with long service life.

- Cast-iron body pumps: Ideal for agricultural irrigation and applications requiring higher pressure.

- Monoblock pumps: Compact designs suitable for narrow wells.

Each model has its own technical specifications. Therefore, water chemistry, temperature, and well depth must be considered during the selection process.

Deep Well Submersible Pump Installation

Correct deep well submersible pump installation is essential for efficient operation. During installation, the pump should not be placed too close to the bottom of the well nor too far from the water surface.

Electrical connections must be watertight, and a check valve is essential in the system. Improper installation may shorten pump life and cause unstable water pressure. For commissioning and start-up, schedule service with technical teams familiar with manufacturer procedures and local standards, such as Poyan Engineering.

Deep Well Submersible Pump Prices

Deep well submersible pump prices vary according to brand, power capacity, material quality, and application. Key price drivers include motor power, body construction, and the level of integrated technology.

The best deep well submersible pump models offer long service life and high energy savings, providing economic advantages over time. For quotations and procurement, contact authorized Grundfos dealers.

Deep Well Submersible Pump Repair

Due to wear or electrical faults over time, deep well submersible pump repair may be required. Common issues include motor failures, shaft breakage, bearing noise, and seal deterioration.

Using genuine spare parts is essential during repairs. For fault diagnostics, repairs, and testing, you can reach out to technical service providers such as Poyan Engineering.

Deep Well Submersible Pump Parts

Every deep well submersible pump consists of components such as the motor, impeller, diffuser, shaft, mechanical seal, power cable, and control panel. Using original deep well submersible pump parts ensures system safety and long-term efficiency.

For brand–model compatibility and stock planning, follow the latest information provided by Grundfos and its authorized network.

In summary:

Deep well submersible pump systems are reliable solutions that enable efficient use of groundwater resources. Seeking support from authorized partners such as Poyan Engineering for selection, installation, maintenance, and spare parts significantly increases system life and performance.